Warehouse Rack Inspection by drone

The Shelf inspection (DIN EN 15635) with the Flyability ELIOS 3 drone enables fast and safe inspection of hard-to-reach areas in the warehouse - with minimum downtime and maximum efficiency for your company.

- Perfect occupational safety

- Extremely fast execution

- Precise reporting thanks to LiDAR

Shelf inspections in accordance with DIN EN 15635: Drone inspections for maximum safety and efficiency

-

Maximum safety

Shelf inspection from the floor. -

Comprehensive inspection

Complete documentation and precise localisation of the findings. -

Time and cost efficient

Avoiding everything that is time-consuming and cost-intensive. -

Meaningful reports

High-resolution photos, perfect localisation of the findings in the point cloud.

A selection of our customers and partners

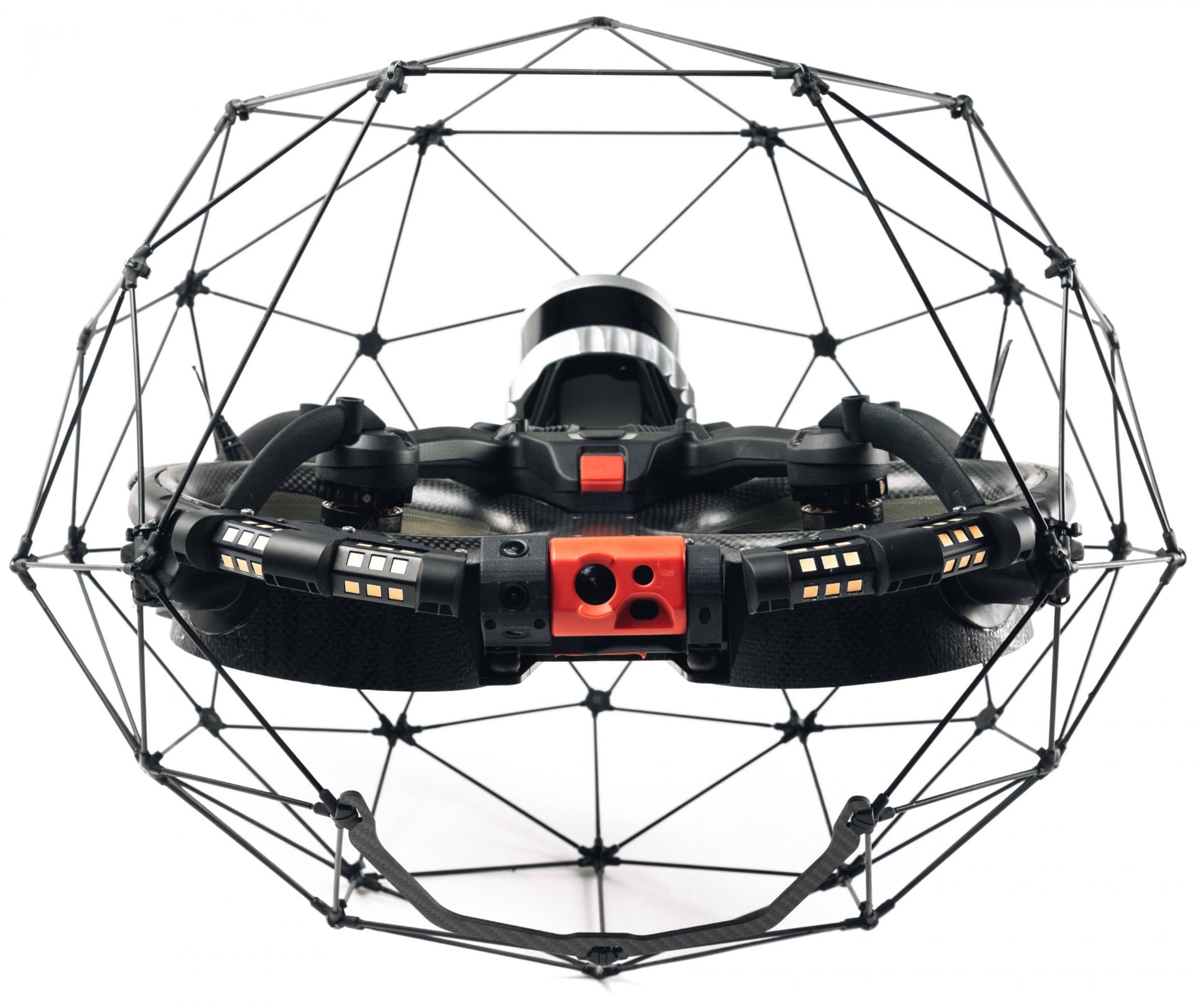

Flyability ELIOS 3: Drone inspections in high-bay warehouses - safety and the shortest possible downtimes

As the person responsible for the safety of a high-bay warehouse, you know how important regular and thorough inspections are.

Damage to racking components such as bent uprights, cracks or loose connections must be detected at an early stage in order to ensure safety and fulfil legal regulations such as DIN EN 15635. However, conventional inspection methods are often time-consuming, expensive and risky.

- With the Drone inspections of the Flyability ELIOS 3 we offer a modern solution that addresses all of these challenges. Our drones capture high-resolution images and accurate LiDAR data that enable a detailed and precise inspection of your high-bay warehouses - without the use of ladders, lifting platforms or scaffolding.

- Although the inspection requires a qualified rack inspector, they can work particularly efficiently thanks to the precise drone images and create the inspection report quickly and comprehensively. This minimises downtime and ensures uninterrupted inspection while your business continues to run.

- The ELIOS 3 drone not only ensures precise results, but also protects inspection personnel from risky work assignments. By using the latest drone technology, you save time and money while increasing safety in your warehouse. The detailed images and reports form a solid basis for targeted maintenance measures and long-term planning to maintain the safety and stability of your warehouse facilities.

- Rely on the Flyability ELIOS 3 and experience how drone inspections, combined with the efficiency of a rack inspector, make your high-bay warehouse safer, more efficient and more cost-effective.

Save time and costs when checking shelves - talk to our experts now!

-

Inspection with minimum downtime

Extremely efficient inspection with the Flyability ELIOS drone. -

Maximum occupational safety

Data is recorded from the ground and reports are generated at the desk. -

Precise localisation of the findings

The ELIOS 3 drone generates a point cloud from which the precise flight path and the location of the damage can be read.

Experts for industrial inspections

What are the advantages of a shelf inspection with the Flyability ELIOS 3 drone?

The Shelf inspection with the Flyability ELIOS 3 drone offers the advantage that even hard-to-reach areas in the warehouse can be inspected quickly and precisely. The use of the drone eliminates the need for complex scaffolding or climbing operations and minimises the downtime of the racking, which makes operations more efficient.

How does drone inspection differ from conventional shelf inspections?

Which racking systems can be tested with the Flyability ELIOS 3?

How safe is the inspection with the Flyability ELIOS 3 drone?

How long does a shelf inspection with the drone take?

Who prepares the expertises and test reports after the drone inspection?

Is the ELIOS 3 easy to operate and do I need special training?

What happens if defects or damage are discovered during the inspection?

Can the drone inspection also be carried out during operation?

The aisle or gear must be unlocked during the inspection. However, the required downtime is comparatively short.

How can I book a drone inspection for my racking system?

-

Inspection with minimum downtime

Extremely efficient inspection with the Flyability ELIOS drone. -

Maximum occupational safety

Data is recorded from the ground and reports are generated at the desk. -

Precise localisation of the findings

The ELIOS 3 drone generates a point cloud from which the precise flight path and the location of the damage can be read.

Request shelf inspection

- We look forward to your enquiry and will respond promptly!